3D CAD services

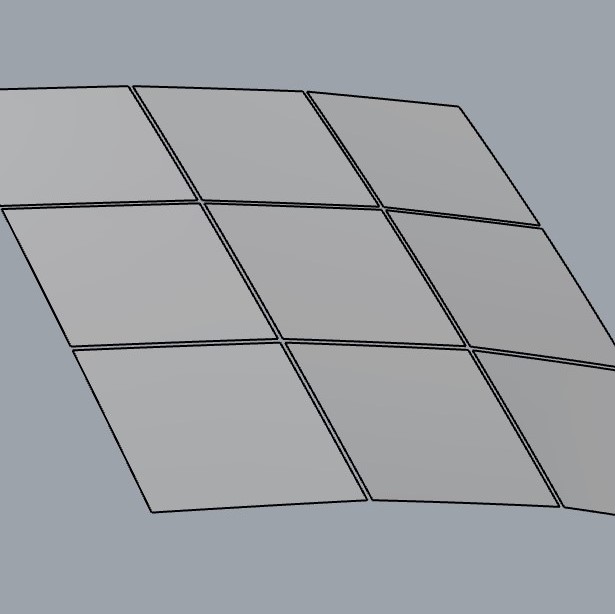

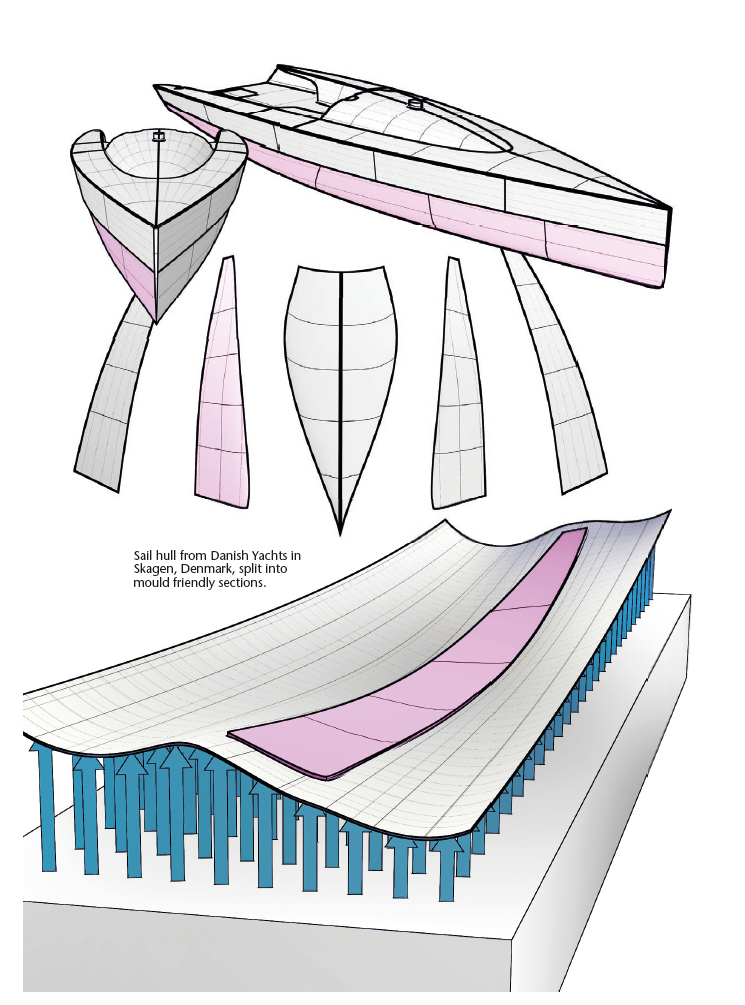

Adapa is uniquely qualified to manage 3D panel processing and quality assurance for paneling to be produced on the Adaptive Moulds.

This is carried out in a close confidential cooperation with the customer, based on a service agreement with clear descriptions of workflow and responsibilities.

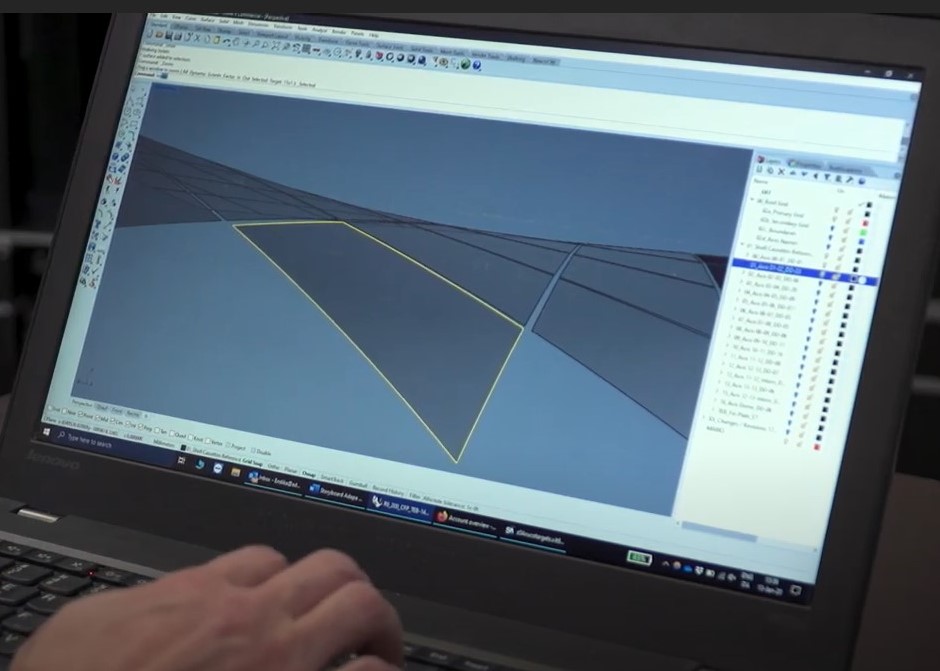

Processing of 3D panels requires relevant know-how in concrete manufacturing as well as deep understanding of the AdapaTools software together with Rhino3D.

Together with the customer Adapa will constantly assists in creating daily files for casting and tailored laser projections to suit the individual casting or placement strategies of the day. In the case of complex panels or other issues, the Adapa service staff will be able to be supported from his colleagues in Adapa.

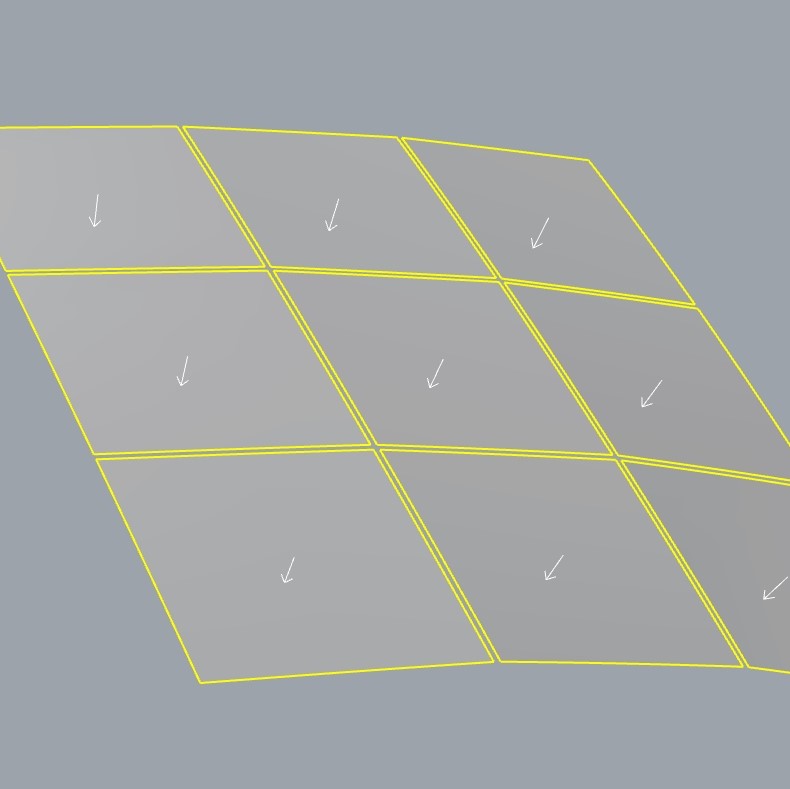

Quality assurance is key in avoiding errors in CAD transformation and projections as well as in the transfer of verified files to the Adaptive Mould. Transfer of files will be documented from the service agreement start, until Adapa places the processed files on individual Adaptive Moulds for manufacturing.

AdapaTools Introduction Video

“Adapa offers remote online 3D/CAD services and for larger projects the service can be offered on-site. The service can also include training of customer personel, to implement new competences in 3D CAD and QC in the organization.”

CAD services may include various tasks, depending on the client

The main components of our 3D CAD service are:

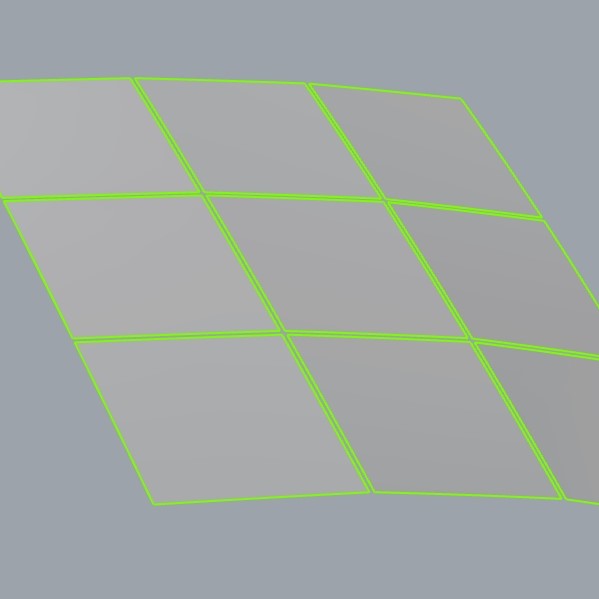

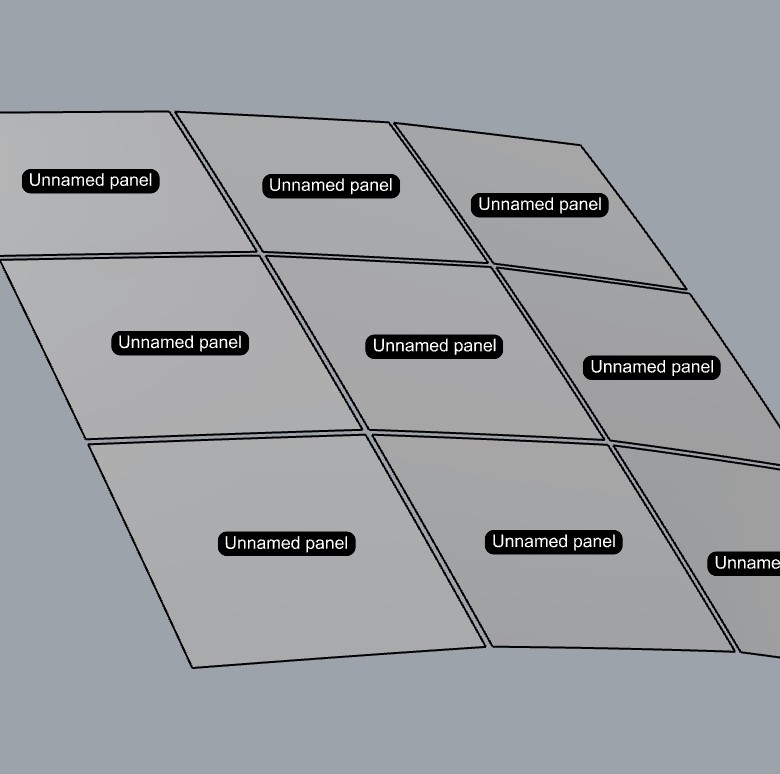

Analysis of a 3D model in Rhino 6 software

to determine which adaptive mould to use and how best to place the panel

Working with the 3D model in Rhino 6 software

to optimize the 3D files in size, details (area, volume, length of sides, length of diagonals, curvature radius etc.) and prepare the input files for the laser and the adaptive mould

Training of customer personnel

to implement the knowledge and routine capabilities the organization needs to operate the adaptive mould and Adapa Tools

Additional tasks agreed

to ensure the full potential in our computer guided 3D mould technology is used in the specific production and organization, we can support in individual tasks

Example list that can be customized to each 3D CAD service agreement:

| Controls and Tasks |

|---|---|

| 1 | Receiving a Rhino file |

| 2 | Downloading a file (one time activity; from 30 sec to 1 hour depending on internet speed and size of a file) |

| 3 | Quick check of a file (one time activity; up to 1 hour) |

| 4 | Confirming transmission to customer (one-time activity; up to 15 minutes) |

| 5 | Sharing a file with entire Adapa team (one-time activity; up to 15 minutes) |

| 6 | Check file (one time activity; up to one day – it requires clearing of all unnecessary layers and going through panels in order to check are they suitable for casting on adaptive mould) |

| 7 | Analyze based on size, complexity of panel as well as production program and which mould to select for production (one time activity; up to two days) |

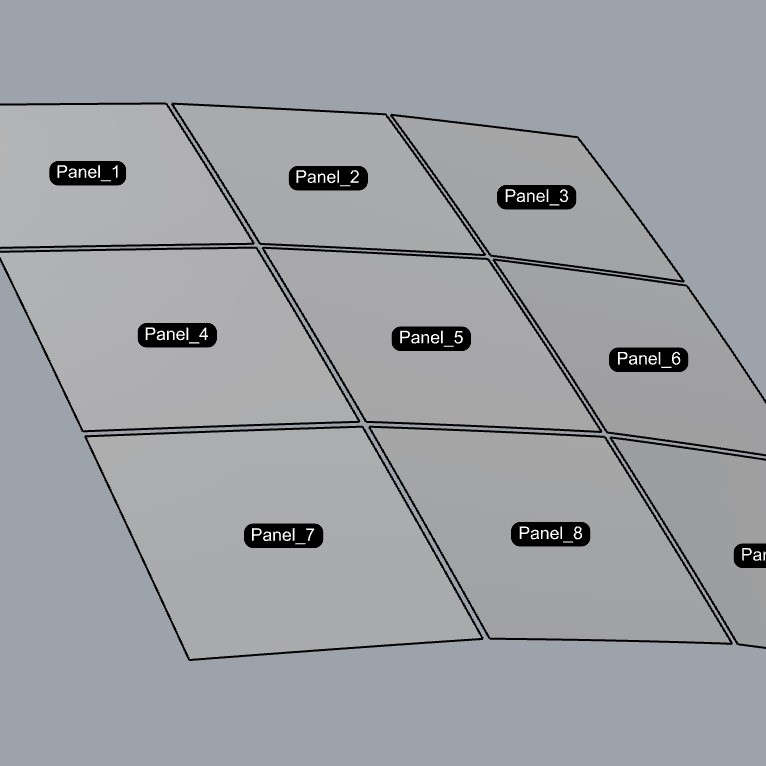

| 8 | Prepare panel for selected mould (multiple activity; up to 5 minutes per panel – depending on original 3D file data structure, Adapa needs to create a panel (solid) which will be later used with Adapa Tools to create a surface on a machine and bottom edge for the laser). |

| 9 | Prepare laser file (multiple activity; up to 5 minutes per panel) |

| 10 | Rename file (multiple activity; up to 5 minutes per panel – Adapa Tools may not be able to use received file names for input files, so Adapa will rename them manually). |

| 11 | Verify file (multiple activity; up to 2 minutes per panel) |

| 12 | Send input files to adaptive mould (multiple activity; up to 30 minutes – depending where and how Adapa is sending it. Internet connection directly to the adaptive mould or with the slower solution by using a USB stick to put the files directly to the control unit. This solution requires multiple agreement from all parties involved in the process) |