Curing Oven for Composites and Thermoplastics

ElectroHeat TS 10066 Curing Oven 2,4 x 1,4 x 2 m panels (LxWxH)

This curing oven is a standard oven from Adapa’s partner ElectroHeat Sweden.

Electro Heat Sweden AB is an innovative company based in Gothenburg. We manufacture and develop heat solutions to companies all over the world.

Rental service is available on the TS 10066 curing oven

The oven is built up by an insulated iron framework and ideal for heating standard types and sizes of composites and thermoplastic. The compact size allows for easy transport and reduces the need for a large oven installation

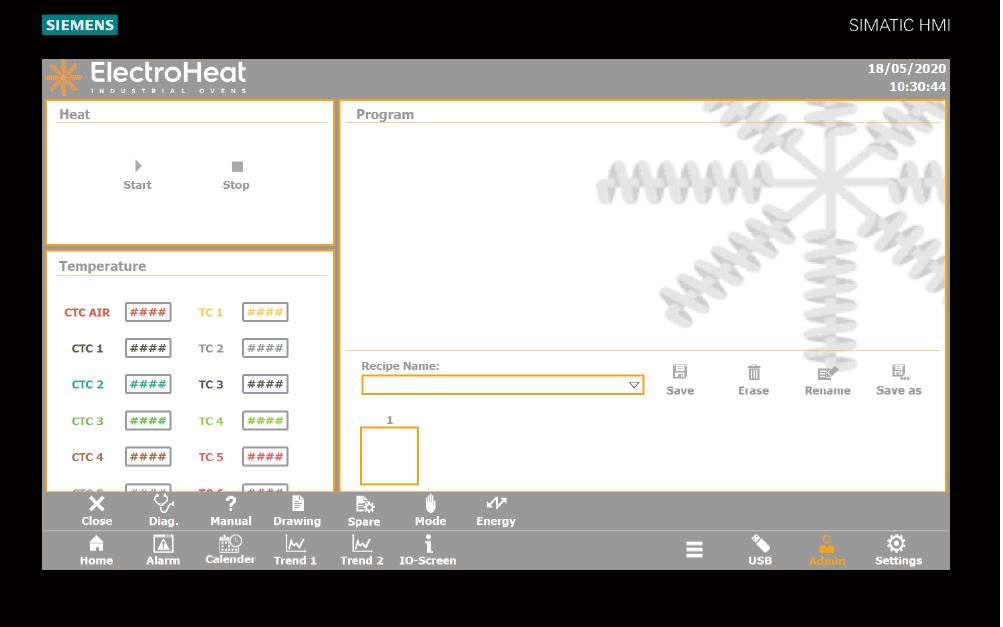

Typically used in work processes with hand lay-up. The HMI is easy to use, and allows for a variaty of control options according to the material properties and preferred process.

Contact us on info@adapa,dk in case of interest, we will direct you to the adaptive mould related contact person at Electro Heat Sweden.

Specification

| Construction | |

| Frame: | The oven is built up by an insulated iron framework. The oven is covered with steel sheets on the inside and with coated steel sheets on the outside. |

| Insulation: | Walls: 150 mm mineral wool Roof: 150 mm mineral wool Bottom: 100 mm mineral wool |

| Heating: | One fan unit with motor, circulation fan, heating elements and over heat protection is placed in the roof. |

| Air inlet: | One air inlet ø80 mm with motor damper is mounted on the fan unit. |

| Air outlet: | One exhaust outlet ø80 mm with motor damper for air ventilation is mounted in the roof. |

| Door: | Manually right hinged door with espagnolette lock |

| Surface treatment: | Grey frame in RAL 7035 Coated Steel sheets in RAL 7035 |

| Control System | |

| Controlling temperature: | One Pt-100 sensor for controlling of air temperature |

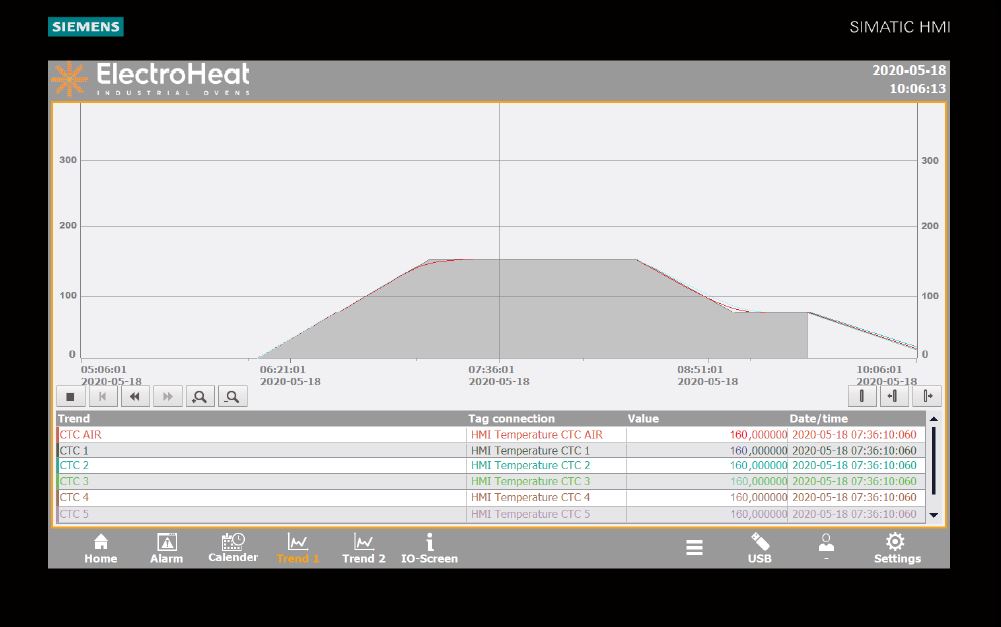

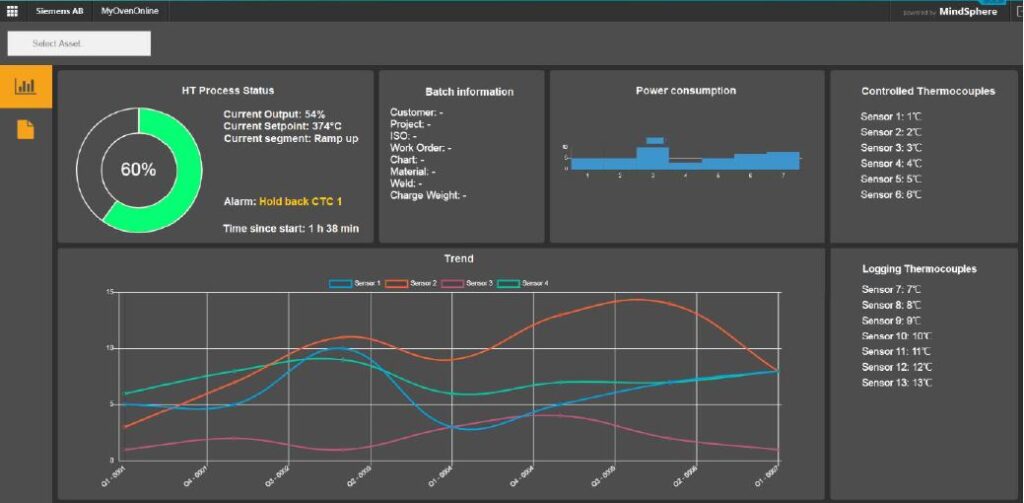

| HMI: | Siemens 9” Panel is placed on the electric cabinet. A standard program for control of heating and cooling contains; Manual temperature setting (°C) View of actual temperature (°C) Up to 30 segments / Program Up to 20 different programs (Recipes) Recipe management; ramp rate, hold time etc. Hold back function between controlling sensors (adjustable ± X°C) Air Temperature Limitation (X°C above set point) Alarm List Logbooks; containing list of trippings, device faults etc. Logging record of all temperature sensors + setpoint Delayed start Standby temperature Logging of power consumption + visual overview Manual Electrical diagram Spare part list Notifications; for service/calibrations intervals etc. HMI in English |