POWER

What needs to be powered?

Electrical power supply for the adaptive mould and the laser projector (if using a laser projector

What is the power consumption of a machine?

The power consumption depends on the quantity of electrial stepper motors and the cycles each day.

Once the machine reach the desired position, is it possible to remove the power?

The power consumption depends on the quantity of electrial stepper motors and the cycles each day.

WHAT IS THE STANDARD POWER CONNECTION?

EU – The control unit is connected to electricity using an external IEC 60309 male socket with a 3P+N+E 6h configuration and 230V/400V 16A. The standard connectors on the adaptive moulds are IEC 60309 plugs with

a 3P+N+E 6h configuration and 230V/400V 16A.

Is there used compressed air?

No, the adaptive mould uses electrical power.

Is there used hydraulic pressure?

No, the adaptive mould uses electrical power.

FACILITY

What if there is dust in the facility?

The cabinet is protected against dust. However it is still recommended to keep the environment as free of dust possible.

Can the machine be moved with a forklift, or will it need a hoist system?

Smaller machines can be moved with a forklift, that can reach the full width of the adaptive mould (from frame side to frame side) and able to expand fork width to ensure the mould does not tip sideways.

MAINTENANCE

How often is maintenance required?

Maintenance is described in the User Manual. The adaptive mould does not contain parts that need regular lubrication. Maintenance mostly consists of daily routines in ensuring the membrane surface is clean and the rod-system is in position.

How do you clean the tool surface?

The silicone composite membrane (or silicone protective sheet) can be cleaned using a brush, water or silicone cleaning agents containing vinegar or alcohol (50/50 diluted) or acetone 50/50 diluted).

For cementious products the water based release agent weberad dem 22 can be used.

How often would someone need to go underneath the adaptive mould?

The most common fault to occur on the bottom (motors and cable side) of the adaptive moulds, is overheating of a motor PCB (above 150 dg Celsius) in hot production facility setup.

We do test the PCB’s and motors in our production, but it may occur that 1/100 PCB’s will have a malfunction within a short period, due to general differences in PCB quality.

In a clean and temperature-controlled facility PCB service should be in rare occasions, with exception of a 2-3 expected general PCB quality failures in the first months. Changing one PCB is a 15-minute job, and only demands general electrical knowledge and a screwdriver.

Can we review your maintenance manual?

The User Manual available on our website is an introduction to the technology and the operation hereof. The full User Manual contains more specific description of the technology and is shared with clients during the specification process.

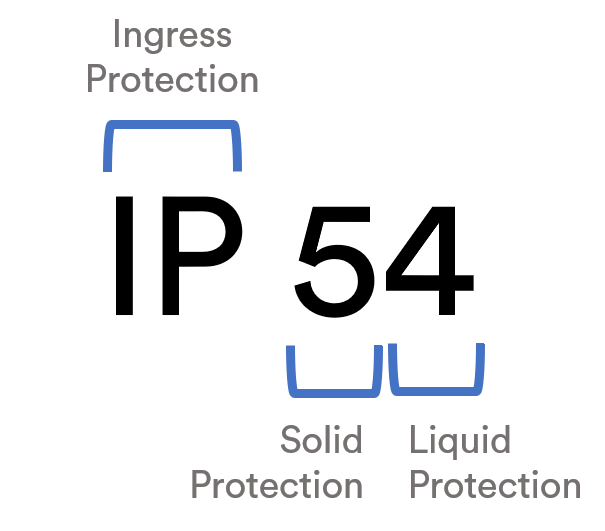

What ingress protection is there for the moving tool?

The electrical stepper motors and actuators are IP54 rated.

USE ACESSORIES

Can silicone adhesives be used?

Do not use silicone-based chemicals on the adaptive mould membrane, like polyester films or tapes coated with a pressure sensitive silicone adhesive , silicon oils or alike.

HEALTH AND SAFETY

Is there a crush hazard?

The space/gap between the membrane support system and the base of the actuators have been evaluated in relation to CE marking.

When the machine is moving into the desired shape, the movement is only going upwards, therefore this does not result in any risk. The gap between the movable parts (membrane and the supporting rod system) and the frame of the machine is 100mm.

It is assessed that the risk of getting crushed is unlikely.

Do you have any recommendations for machine guarding/safety improvements?

When the machine is started the operator must ensure that no other personnel is within the proximity of the machine. Turn off power when in shape or in 0-position, making the adaptive mould a stationary non-movable device.

General Technical Articles

-

Adapa A/S has completed assessment of the adaptive mould technology for compliance to CE marking rules

Our adaptive mould technology ...

-

Download AdapaTools

Download of AdapaTools for fre...

-

Fabricate 2020 and adaptive moulds

We recommend reading the Fabri...

-

Handling of Adaptive Moulds

We have made lifting and handl...

-

IP Codes in accordance with IEC 60529

We recognize our customers nee...

-

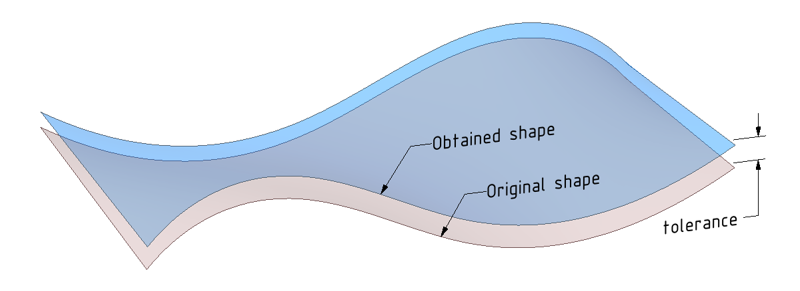

Precision and the definition of tolerance

We understand the perspectives...

-

Product Safety Labels

We target safety signs to glob...

-

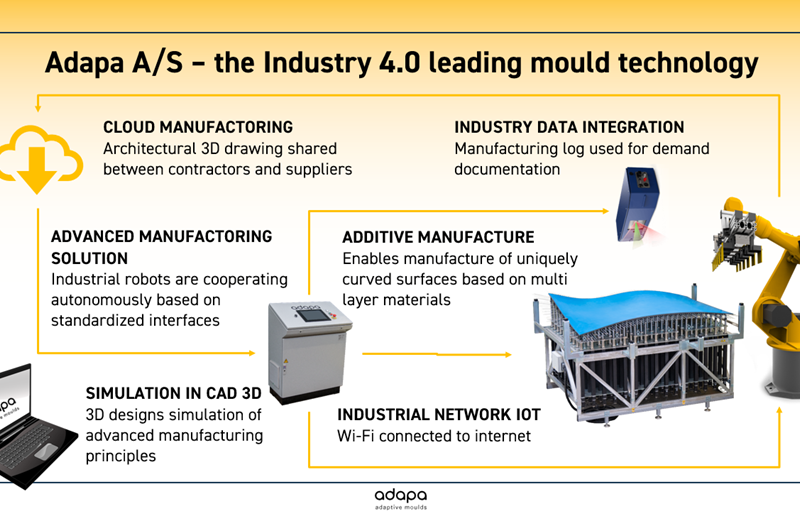

THE ADAPTIVE MOULD FOR INDUSTRY 4.0

Past Industrial Development Fo...

-

The definition of surface roughness

Surface beauty and definition ...