Fabricate 2020 and adaptive moulds

We recommend reading the Fabricate 2020 book and wishes to highlight the important and fundamental progress achieved by Werner Sobek AG, by bringing in cutting edge technologies in a well-designed and well-planned production process. Please find excerpts for recommended reading below.

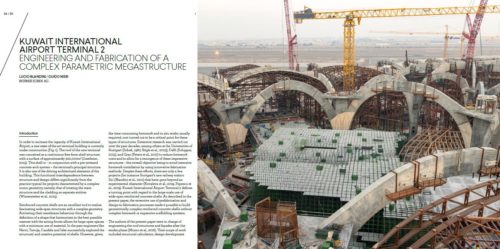

KUWAIT INTERNATIONAL AIRPORT TERMINAL 2

ENGINEERING AND FABRICATION OF A COMPLEX PARAMETRIC MEGASTRUCTURE

LUCIO BLANDINI / GUIDO NIERI

WERNER SOBEK AG

In order to increase the capacity of Kuwait International Airport, a new state-of-the-art terminal building is currently under construction. The roof of the new terminal was conceived as a continuous free-form shell structure with a surface of approximately 320,000m2.

Burry, J., Sabin, J., Sheil, R., Skavara, M., (eds.).

Available to download free: www.uclpress.co.uk

Page 84 – “Kuwait International Airport Terminal 2 defines a turning point with regard to the large-scale use of wide-span reinforced concrete shells. As described in the present paper, the extensive use of prefabrication and design-to-fabrication processes made it possible to build geometrically complex reinforced concrete shells without complex formwork or expensive scaffolding systems.”

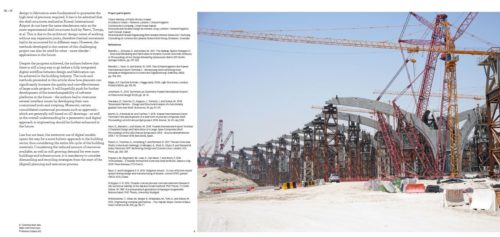

p 86 – “The present paper describes the process and the challenges linked to this project, outlining among other things the difficulties encountered in addressing different aspects (geometry, calculation, production, etc.) and in developing specific engineering methods, and

interfaces between various software platforms, as well as the integration of cutting edge fabrication technologies (i.e. adaptive moulding) within the constraints of such a megastructure.”

Page 89 – “In order to produce the 37,000 cassettes (with a total of almost 13,000 different geometries), 85 adaptive moulds were used. The cassettes were cast on a reconfigurable surface which could be adapted according to the information from the CAD model. Contrary to the common way of producing moulds for double curved geometries (namely manufacturing them by CNC milling foam materials), an automatic process was developed, thus avoiding labourintensive operations and waste production. The surface achieved was so smooth that no manual post-treatment was required.”

p 90 – “This is a clear step forward in comparison with classic shell structures of the 20th century. Moreover, the development and integration of automatised processes and a direct chain of control fromdesign to fabrication were fundamental to guarantee the high level of precision required.”

Fabricate 2020

Burry, J., Sabin, J., Sheil, R., Skavara, M., (eds.). Available to download free: www.uclpress.co.uk

is the fourth title in the FABRICATE series on the theme of digital fabrication and published in conjunction with a triennial conference (London, April 2020). The book features cutting-edge built projects and work-in-progress from both academia and practice. It brings together pioneers in design and making from across the fields of architecture, construction, engineering, manufacturing, materials technology and computation. Fabricate 2020 includes 32 illustrated articles punctuated by four conversations between world-leading experts from design to engineering, discussing themes such as drawing-to-production, behavioural composites, robotic assembly, and digital craft.

Editors: Jane Burry, Jenny Sabin, Bob Sheil, Marilena Skavara

Copyeditor: Clare Hamman

Design: Patrick Morrissey / Unlimited Printing, Albe De Coker, Antwerp, Belgium

First published in 2020 by UCL Press, University College London, Gower Street, London WC1E 6BT

This book is published under a Creative Commons 4.0 International licence (CC BY 4.0). This licence allows you to share, copy, distribute and transmit the work; to adapt the work and to make commercial use of the work providing attribution is made to the authors.