Configure your adaptive mould

With our expertise in reconfigurable moulds and your expertise in materials and production processes, we can jointly configure the optimal Adaptive Mould solution.

We engage with our potential customers in a close technical dialogue to identify the 6 key parameters that need to be locked-in before we start putting together a solution for them.

The 6 Solution Parameters to Identify

Main considerations during configuration

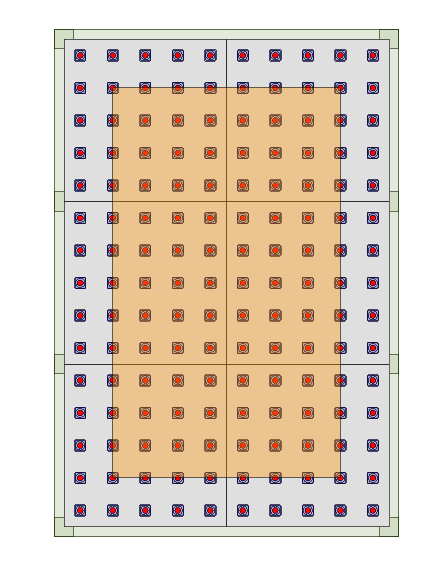

Total Area Limitations

It is possible to cast on the outer area, defined by the distance between the number 1 and 2 actuator, however the tolerences may not be according to specification.

Active Area Specification

All specifications regarding curvature radius and tolerances are within the active area of the adaptive mould. Utilizing the outer area, is an optional way of increasing utilization og the adaptive mould.

Total Area (grey) – Active Area (orange)

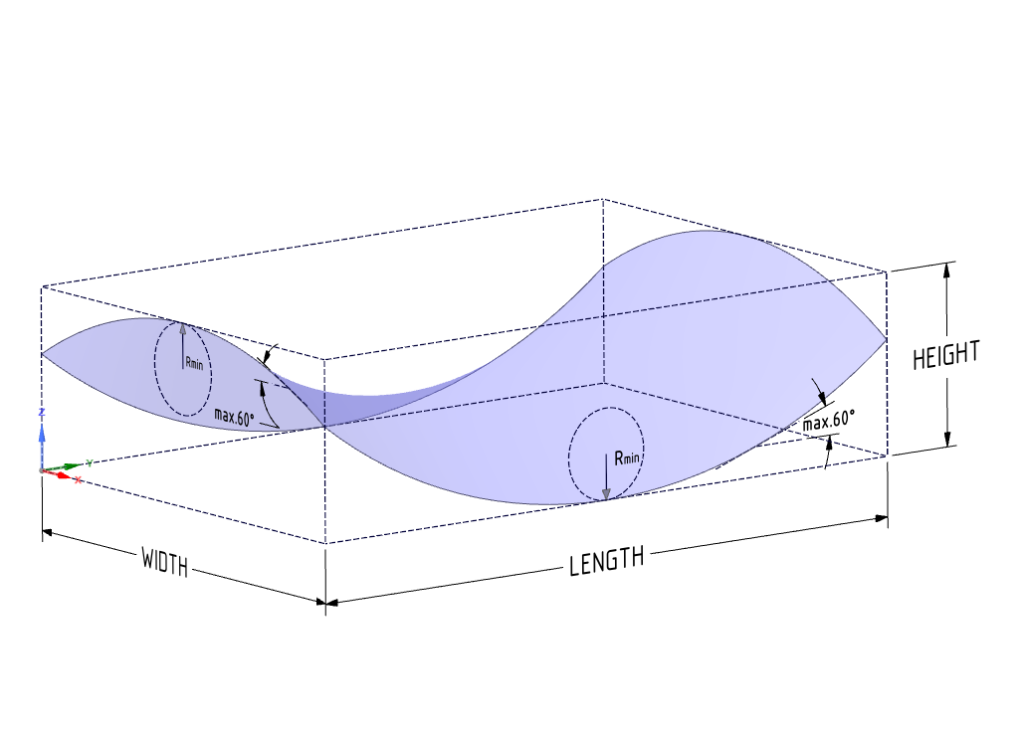

Maximum Angle

The mould can reproduce surfaces with slopes of up to 60 degrees (customizable). The angle of this slope is measured with respect to the moulds surface when flat (which coincides with the base plane of the bounding box); Therefore the orientation of the surface on the mould has an impact on its reproducibility.

Although our software will automatically choose the right bounding box, and therefore the orientation of the target surface, the user can also do this manually.