Handling of Adaptive Moulds

We have made lifting and handling easy

We acknowledge the customers need for setting up a flexible production layout, so in general we design our Adaptive Moulds in a way that facilitates easy movement of the mould within same production facility or even relocating it for the purpose of a project related production.

Some of our customers choose to rent a mould for a small project or the initial mockup testing production. In these cases, the transportation cost is kept at a minimum due to weight reduction and transport friendly design of our Adaptive Moulds.

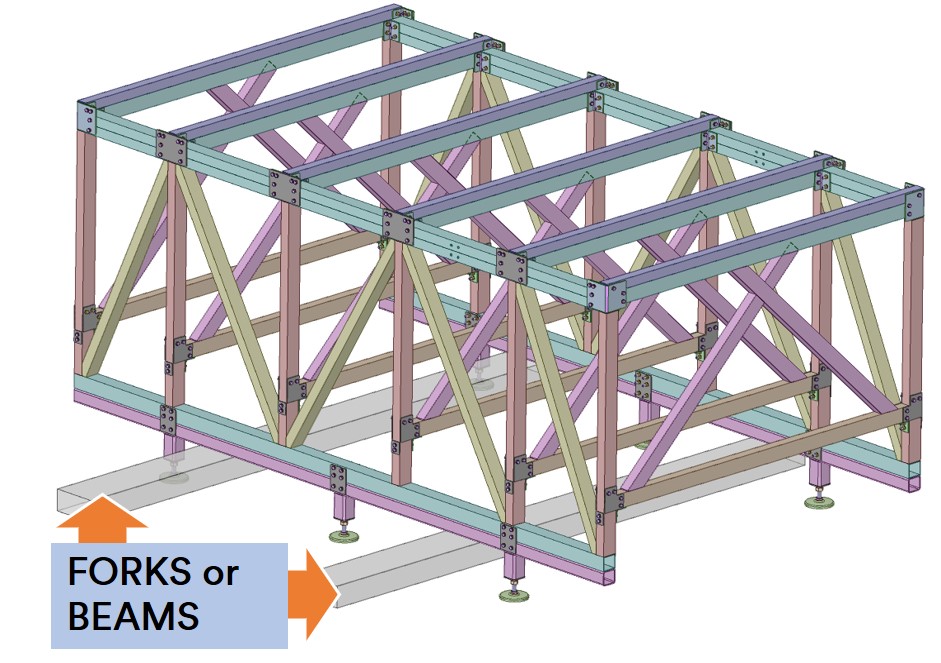

Use a forklift or a crane

There are two ways of lifting our Adaptive Moulds. Either by forklift or by crane. In both cases the principle is to lift the Adaptive Mould from underneath. It is safe to do that because of the steel beam at the very bottom that takes the whole load. The placement of either forks or beams underneath the Adaptive Mould, is indicated by the lifting signs.

Lifting the Adaptive Mould by the upper frame or underneath the membrane supporting system, is to be avoided at any time.

After the successful movement of the Adaptive Mould, the Adaptive Mould feet are to be adjusted correctly and a full calibration of the adaptive mould and laser must be done again.