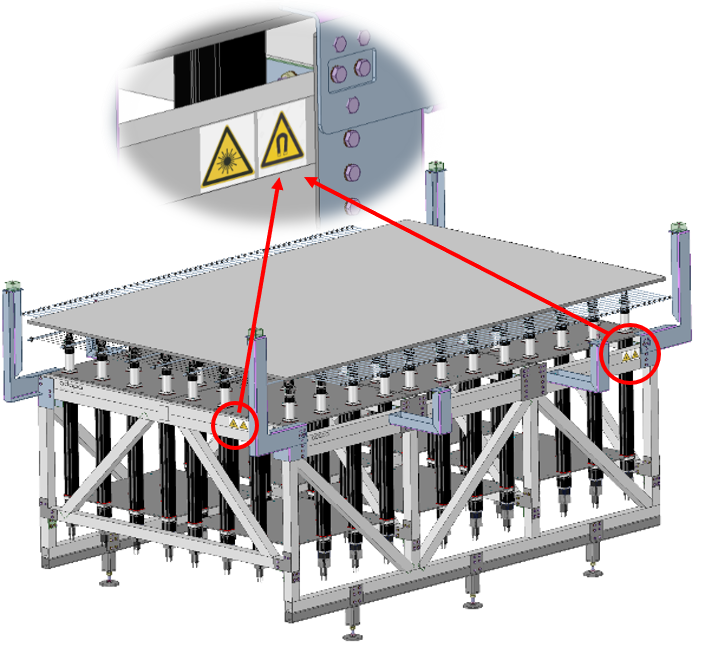

Product Safety Labels

We target safety signs to global customers

Adapa A/S distribute adaptive moulds in multiple markets and continuously strive to support our global customers in utilizing our fast and flexible moulding technology, while at the same time securing a high level of personnel safety.

To comply with the required global standards and secure the information is conveyed across language barriers, we use well-designed symbols on safety labels.

Safety Labels are a key part of the Information for use provided by machine builders to users and are often the only information that many users get to see. This makes the content, design and placement of the safety labels critical to their effectiveness. There is always a risk in the under-use of safety labels or in the over-use of safety labels. We have chosen to use standard labels and are aware this increase the number of labels, but on the other hand the well-known symbols are easier to recognize to the user.

SAFETY FIRST

Adapa’s safety symbols are selected based on the Product Safety Label Standard ISO 3864-2 and the Machinery Directive in EU.

The main hazards on our products

We focus on 3 potential sources of safety hazards on our adaptive moulds. They are related to the electrical installations, magnetized material and the laser beam from laser projectors. The safety signs for all the potentially hazardous situations is the same. An equilateral triangle in yellow/black configuration that symbolizes ´Warning message´!

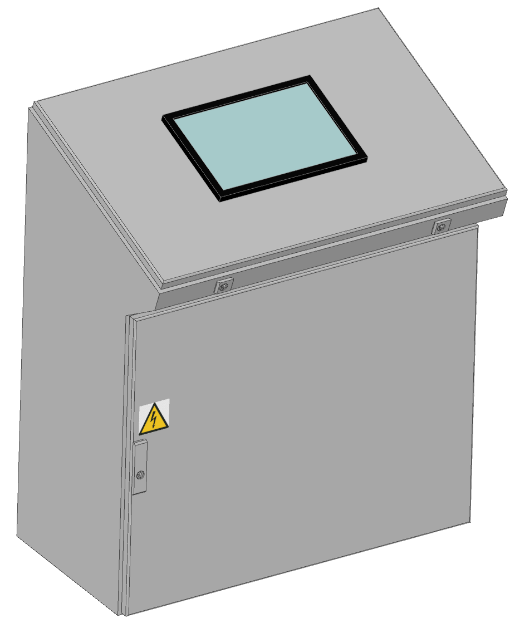

Electrical cabinet

Electrical installations within the electrical cabinets are potentially hazardous, where it is necessary to take precaution before opening the cabinet. Use of electrically insulated gloves and other means of protection Is recommended. If not avoided minor or moderate injury could occur.

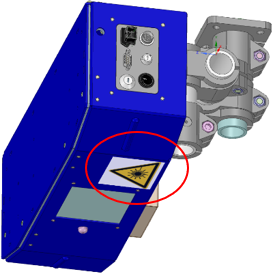

Laser projector

Laser beams are of m2 quality and which means that it is not particularly dangerous for the eyes of the user. The potentially hazardous situation lies within prolonged looking into the source which might lead to temporary blindness that temporary disables the user. Safety equipment is not necessary. The user shall be aware of the presence of laser beams.

Magnets within the membrane system

Neodymium magnets within the Membrane Support System are potentially hazardous, where it is necessary to take precaution before coming into contact. Electronical and other magnetized equipment should be stored away when close. If not avoided minor injury could occur.

Pacemaker warning

In addition to the Magnetic Field sign, a specific warning targeting Pacemaker and Metallic implants is placed next to the yellow/black triangle.

Please secure the safety signs are visible

It is well recognized that in many instances, well designed and properly placed safety labels can increase operator and maintenance personnel awareness of the inherent hazards involved when working with machinery.

When installing labels on equipment we keep in mind the following criteria:

– Label needs to be readily visible to the target audience (personnel that may be in contact with the hazard)

– Label needs to alert the viewer to the hazard in time to take appropriate action.

– Labels are required to be applied on or adjacent to the area where the hazard is present.

– Labels are required to be permanently affixed to the equipment.